What Are Fasteners?

Photo by Appalachian Log Structures

Fasteners do more than hold logs together. They are used for alignment during assembly of the log wall and they hold joints and corners together to restrict the twisting of logs as the wood seasons (dries). There are two types of fastening techniques used to connect wall logs -- mechanical fastening and adhesive bonding. Mechanical fasteners include bolts, drift pins, lag screws, log/timber screws and spikes. Adhesive bonding is accomplished by placing a bead of mastic or sealant product along the length of the log. Some log builders use a combination of mechanical fastening and adhesive bonding.

Bolts

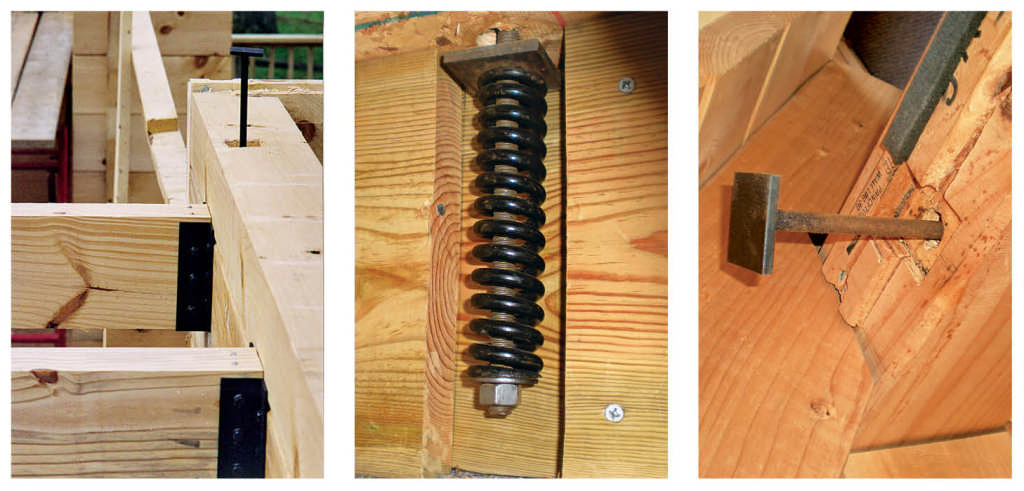

Bolts are used in two basic areas of log construction. One application joins logs in a wall; the other joins logs that form a beam or header. In the latter application, bolts are used to improve the structural capacity of logs stacked together. Merely stacking the logs forces them to act independently. By installing a specified pattern of threaded rods with nuts and washers on each end, the logs act collectively to form a strong beam. The second -- more common -- application of bolts used in log wall assembly is called 'thru-bolt' fastening. A thru-bolt runs the full height of the log wall, through all log courses and is held by a nut and washer on each end (under the subfloor or sill log and above the top log course). Pressure is maintained on each end of the thru-bolt by occasional manual re-tightening or by using springs or other specially designed mechanisms, which creates a compression force to keep the log wall tight. This same fastening system acts as a tension rod, limiting log separation during high wind or earthquakes. Thru-bolts are installed near the ends of walls, at openings and often spaced along the log wall 4 to 8 feet apart. Bolt diameters range from 1'2" to 11'2" and are available with thread at both ends, full-length thread (called all-thread), or thread at one end and a head at the other. An advantage of thru-bolt fastening is that it allows logs to move along the bolt as wood seasons, accommodating settlement (considering the drilled holes in the logs are equal to the diameter of the bolts). A disadvantage to thru-bolt construction is the assembly process. As bolts are set in place, each log is drilled to match bolt locations, then lifted over the bolt and set in place. To ease the difficulty of lifting a heavy, pre-drilled log over a tall bolt, shorter lengths of bolt (typically 30" or 36") are joined with threaded couplings. Where couplings are required, the log(s) must be drilled to accommodate the larger coupling diameter. And, unless a compression device is incorporated, the thru-bolt system involves periodic manual tightening of the nut above the top log course over the first couple years as the logs settle.